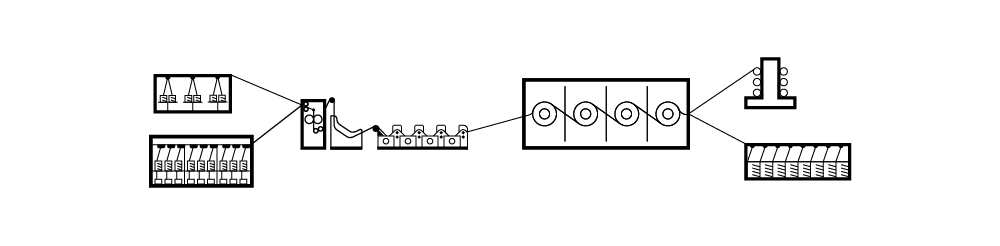

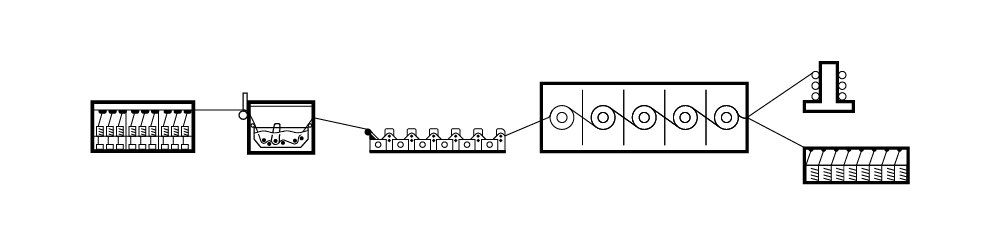

PLANT COMPOSITION

EXAMPLES OF CONFIGURATIONS

BACKWASHER LTT

BACKWASHER LNT

BASOLAN IR

CHLORINE/HERCOSETT IRS

Dyeing TCT

Dyeing TCN

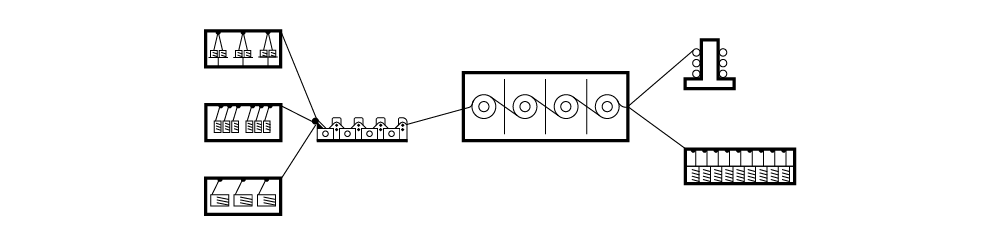

BACKWASHER LTT

DYED TOPS “LTT” type

BACKWASHER LNT

DEYED TOW “LNT” type

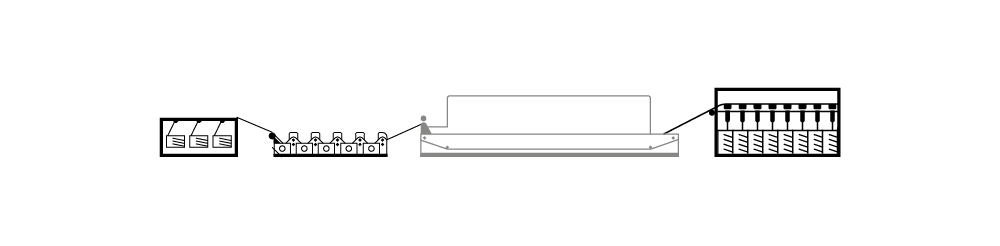

BASOLAN IR

INSTALLATIONS FOR WOOL TOPS SHRINK PROOF TREATMENT

BASOLAN® and others of the “IR” type

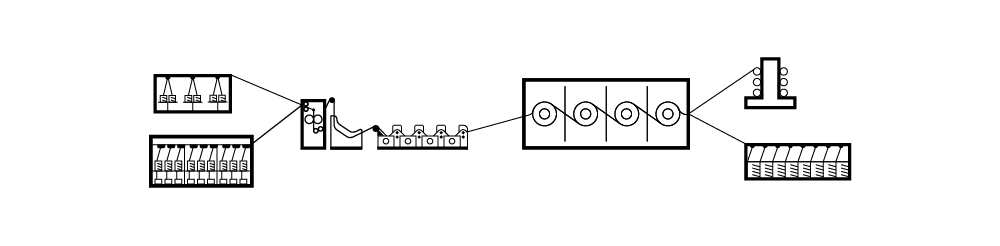

CHLORINE/HERCOSETT IRS

INSTALLATIONS FOR WOOL TOPS SHRINK PROOF TREATMENT

CHLORINE/ HERCOSETT® “IRS”type

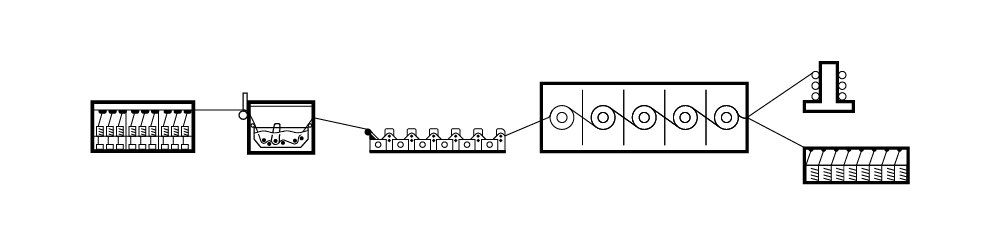

Dyeing TCT

Continuous Dyeing Plants

Wool TOPS “TCT” type

Dyeing TCN

Continuous Dyeing Plants

Acrylic TOW “TCN” type

FEEDING SECTION

The following input creels can be selected:

- With coils and bumps supports

- For bumps on trolleys

- For Big-Form Tops or Tow Cheeses

- For Tops to be unwound both from inside (Défilé) and/or from outside (Déroulé)

- For Tow in bales

PADDING SECTION

- Impregnating padder “Foulard” with stocking-up chute for shrinkproof treatment ranges

- Impregnating padder “Foulard” with apron steamer for continuous dyeing plants

- Chlorinator for superwash treatment

TREATEMENT SECTION

Set of backwash bowls each one complete with squeezing press.

The number of bowls depends on the type of the treatment to perform (usually from 3 to 6 units)

INPUT CREEL

Also known as the unwinding machine, pulls out the wool from the bumps.

INPUT CREEL

The wool is taken from the bumps and placed on the conveyor belt.

FOULARD / BASOLAN

This treatment gives a slight anti-pilling effect and a soft, fluffy and voluminous hand.

CHLORINATOR > EASYCARE treatment

The result is the machine washable wool, very shiny, bright and with an extremely soft hand. It’s also possible to apply the anti-fungus, anti-tar, anti-odour substances.

TRANSITION FROM THE CHLORINATOR TO THE BACKWASHING MACHINE

CHEMICAL STATION

The dosing station equipped with the flow meters.

DOSING STATION

The tanks with the control of the consumption of water used for rinsing and in case of machine stopping.

BACKWASHER

Neutralises chemical treatments, washes and polymerises the wool.

BACKWASHER

Backwasher’s cylinders and dryer entrance.

DRYING SECTION

- Tops handling perforated drum dryer (from 2 to 7 drums)

- Tow handling apron dryer

EXIT SECTION

One of the following configurations can be chosen:

- Exit in balls for Tops.

- Exit for stationary cans for Tops.

- Exit in rotating cans for Tops.

CHEMICALS DOSING SECTION

Fully automated chemicals’ storage, preparation, dosing and feeding station.

HYDRAULIC CONTROL UNIT

DRYER

Low temperature and high speed wool drying. This dryer is equipped with overlapping cylinders and high efficiency fans for air recirculation.

DRYER EXIT

Tops’ exit from the dryer towards the output creel.

SWITCHBOARD

ELECTRONIC COMPONENTS

Details of the electric installation.

MANAGEMENT SOFTWARE

The visual appearance of the control and management system is comprehensible and reliable. Is allows the operator to display constantly the most important parameters.

Automation and process management software

Includes PLC, Siemens software and Mitsubishi handling.

OUTPUT CREEL

Collects the slivers of the treated material into coils or in one meter diameter rotating cans.

OUTPUT CANS

On the output creel’s platform there are fitted several rotating discs; One collection vessel is placed on each rotating disc.

Request your personalized quotation